Updated 27 Jun 2014

|

Planting a new oakwood in Dorset

|

|

This essential job needs either the teeth of sheep and cows

or costly equipment. Cows and sheep leave a frightful mess,

so we went for the hi-tech option.

It involves:

Mowing,

Raking,

Baling,

Wrapping and

Loading.

The end product is BALAGE.

There is a lot on Google

about the pros and cons of these large, plastic-wrapped

Swiss-rolls of grass.

Wrapping bales with polythene film

(Silotite) is an exacting operation.

The contractor used was

Philip Trim Contractors of Wareham, Dorset.

See also the Yield in 2012 in a record wet summer.

|

63.

Owen, neighbouring farmer who organises all this.

|

63a.

Peter has mowed grass every daylight hour for 6 weeks. He asked me

"Have you been pulling weeds?", "No, why?", "Because there

aren't any". Nice complement!

|

63b.

With cutters ahead, port and starboard, 20 acres took 100 minutes.

|

63c.

Pollen smoke rises from the grass, drivers can't have hay-fever!

|

63d.

Squeezing into the next field, next time prune the hedge first.

|

63e.

Finishing off field #4.

|

63f.

The mown grass lies and dries, ready to be raked.

|

63g.

The "teeth", scissors that do the mowing.

|

63h.

Shaun with his raker.

|

63i.

The rakes throw the grass inward, hitting a buffer, it then falls down.

|

63k.

Raking into a line.

|

63j.

Grass raked into a line, ready for the baler.

|

63L.

Lifting rakes for turning.

|

63m.

Rakes vertical to get through hedge into next field.

|

63n.

The baler makes a "Swiss Roll" and winds twine round it.

|

63o.

Dropping a bale.

|

63p.

A bare bale, wound with twine but without plastic film wrapping.

|

63q.

Loading a bale into the wrapper.

|

63r.

Wrapping with Silotite plastic film (various colours available).

|

63s.

Lifting a bale onto the transporter.

|

63t.

Loading the transporter with bales.

|

63u.

Transporting 24 bales to our customer during the 2nd cut in September.

The first cut (math) in June yielded about 170 bales from 20 acres.

The second cut in September (aftermath) yielded about 70 bales.

2008 Jan-mid Sep has seen 778 mms of rain, unusually wet, but dry weather

for 12 days before the aftermath brought in a good harvest and pleased

our customer. The 4 fields look healthy and probably will need no spraying,

either with fertiliser or against thistle. 2008 has been a very good year for

sweet grass, the speciality of Bear Mead.

|

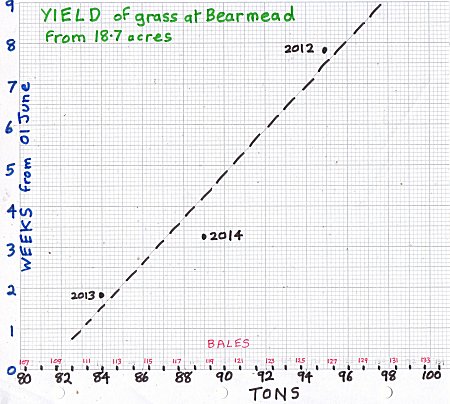

Cut 25jul2012 13jun2013 23jun2014

Wrapped 25jul2012 14jun2013 26jun2014

Per Per Per

Field Acre Bale acre Bale acre Bale acre

1 6.36 49 7.7 42 6.6 41 6.4

2 5.46 35 6.4 28 5.1 30 5.5

3 3.78 25 6.6 23 6.1 26 6.9

4 3.13 18 5.8 19 6.1 21 6.7

Tot 18.73 127 112 118

Tons 95 84 89

Weight of each bale =2.5 bales per ukton

Diameter of each bale=130 cms.

Length =125 cms.

Volume of each bale =1.658 cu metres.

Weight of each bale =406 kg=895 lbs.

Total volume =210.6 cu metres.

Est total weight =51,562 kgs=50.7 uk ton.

Total yield =11.1 cu metres/acre.

=6.69 bales/acre.

=2.67 uktons/acre

16jun2013: A bale was weighed at 0.75 ton

using extendable arm on tractor

112 bales x 0.75 ton = 84 tons from 19 acres.

|

63v.

Grass yield over recent years.

|

from Corfe Mullen Inclosure map

and List of landowners 1840

Acre=4,047 sq m = 0.405 hectare = 4 roods

Rood=1,012 sq m = 40 perches

Perch = 25.3 sq m

Hectare=10,000 sq metres

Fields A R P Ac R P Sq mts ac ha

1 438 (06-1-18) 06+1+18 25,749 6.36 2.57

2 435+436 (01-2-00)+(01-2-11) 04+5+34 22,108 5.46 2.21

+437 +(02-1-23)

3 431+432 (00-0-41)+(01-2-04) 02+6+45 15,304 3.78 1.53

+433+434 +(01-2-04)+(00-2-13)

4 440+439 (02-2-08)+(00-2-13) 02+4+21 12,673 3.13 1.27

5 443+441 (05-2-01)+(00-3-33) 05+5+34 26,155 6.46 2.62

Totals 19+21+152 101,989 25.20 10.20

|

River and groundwater levels

|

In 2012, a record wet June and July forced a delay in

cutting and baling by about 7 weeks to 25 July. A heavy flood

on 9 July flattened the grass and laid a lot of silt down.

The choice of black plastic with temperatures around 28°C

on baling may have been a mistake.

|-----------------------------------------------------------

(7 week delay)

------------------------------------------------------------|

|

31 May 2012 - 28 Jun 2012

|

29 Jun - 27 Jul 2012

123456789012

FLOOD-15

|

|

5 Dictionary results for the word "AFTERMATH"

- A new growth of grass following one or more mowings, which may be grazed, mowed, or ploughed under.

- A second growth or crop in the same season, as of grass after mowing.

- 1523, originally a second crop of grass grown after the first had been harvested.

[The -math is dialectal, from O.E. męš "mowing," from P.Gmc. *męthan. Figurative sense is from mid-17c.]

- A second mowing; the grass which grows after the first crop of hay in the same season

- A second crop, as of grass that grows after the earlier mowing

|

All you ever wanted to know about balage

Balage is an increasingly popular winter feed option.

It's nutritious and most animals enjoy it, but there are risks.

Neil Clarkson reports on strategies to minimise those risks.

Pros and Cons

Pros

- Your crop is far less likely to be ruined by rain.

- You can store it outside.

- It retains more food value than hay.

Cons

- It's more costly than hay.

- Bales will be at least twice as heavy as their hay equivalents.

- Specialist gear is needed to move big bales, or you need to employ a

contractor to do it.

- You need to check regularly for holes and repair them.

- Once open, bales need to be fed out within a few days.

- Storage life can vary from bale to bale.

16 June 2007 -- There's nothing like a disastrous hay season to get

farmers thinking about their options. Some think about balage - those

big plastic-wrapped bales of grass that dot the countryside in increasing

numbers as the summer progresses.

Balage is grass that is baled and wrapped soon after cutting, minimising

the risk of loss through rain.

While some contractors now offer wrapped small bales, most is made in

rounds, or big or medium squares. These bales can be stored outside,

which will appeal to many, but once cut open they must be fed out within

a few days. While balage is more costly than hay you have to weigh that

against the higher food value.

Like hay, things can go wrong. There are also risks in feeding it, which

we will consider later.

What is balage?

Balage, silage, and haylage are names for the same basic product:

ensiled grass. It doesn't matter whether the grass is going into a

massive silage pit or a plastic-wrapped bale - the process is the same.

The grass is baled when much greener than hay. Hay is typically baled

with a moisture content between 15% and 17%. Ensiled grass is typically

between 30% and 60%, with the most stable balage usually made in the

higher half of that range.

The grass may only be cut for a day or even less before the balers arrive.

The grass needs to be good quality with a high sugar content. Coarse,

stemmy grass will not only make inferior balage, it is also more likely

to puncture the plastic wrap.

The contractor needs to produce a good tight bale with as little air in it

as possible. Loose bales are unlikely to make good balage. (When silage

is being made, a digger will trundle backwards and forwards over the grass

for hours, compacting the heap as much as possible.)

Dealing with and preventing holes

There's little point in making balage unless you're going to be diligent

about keeping it sealed up. Farming stores sell tape for the purpose, so

get some before the bales are made. Use the tape to seal up holes as soon

as you find them.

Set aside an area for storing the bales where no stalky material or sharp

stones are likely to puncture the bottom of the bales.

Check them over carefully for holes once wrapped, and seal them up with

tape. Check again once they're moved off the paddock.

Stock will chew through balage plastic so erect temporary fencing if

necessary to keep animals out.

Birds can puncture bales with their talons and beaks. Some farmers store

their balage close to busier areas so birds don't get free rein.

Heavier bales are more likely to be damaged when being moved.

Pay the contractor to put extra wrap on each bale. More plastic means less

chance of holes. It has been suggested that two extra layers is as good as

using inoculant.

Keep children and pets from climbing on the bales.

Don't store the bales where you know porina to be a problem.

Soon after, the plastic wrap goes on, sealing the grass from the outside

world. The ensiling process is about to begin. A combination of natural

plant respiration and the action of aerobic bacteria begin to heat the

bale, much as you would expect in a compost heap. But aerobic bacteria

need air and, on a warm day, a wrapped bale can be all out of oxygen in

30 minutes. However, if conditions are cooler, or there is too much air

in the bale, this process can take hours, sometimes even days.

A well-compacted bale may heat as little as 3degC before it runs out of

air. Grass baled when drier is likely to have more air trapped in it, and

the heating process can continue too long. Once temperatures of 40degC or

more are reached, the grass will suffer heat damage and blacken, sometimes

costing more than half the available protein.

Generally, the quicker this aerobic phase is over, the better, because

the goodies you want to feed out to your animals are being used up.

Bacteria are turning useful water-soluble sugars into carbon dioxide and

water, with heat being a major byproduct.

Once the oxygen is gone, this aerobic heating phase will end. However,

waiting in the wings are anaerobic bacteria, which function without the

need for oxygen. They multiply rapidly and begin to ferment the grass,

turning the plant sugars into organic acids - mainly lactic and acetic

acid. As this continues, the bale becomes increasingly acidic.

Once it reaches a pH of about 3.8 to 5.0, the anaerobic bacteria find the

going too tough and the fermentation process grinds to a halt. The bale

has reached a stable state, ready to ride out the months until it is fed

out. All should remain well unless the bale is punctured and oxygen

penetrates.

It's important to have enough sugar in the bale to drive the fermentation

and drop the pH to a level that will result in stability. If the bale runs

out of steam at a pH above 5.0, undesirable clostridial bacteria can take

hold. Fermentation will be incomplete and the bale will be less stable,

and its life much shorter.

This is why it's important to use grass when it's younger and still has

high sugar levels. Some contractors will not cut the grass until after

lunch. The longer the sun is on the grass, the higher its sugar content.

While the ultimate pH achieved in your balage is important, the speed at

which it gets there is also critical. The longer the bale stays outside

the desired pH range, the more likely that bad bacteria can take hold.

Moisture content is critical

Correct moisture content is considered one of the most critical elements

in successfully making balage, along with high sugar content. The usual

range is 30% to 60% moisture, with the most stable balage usually being

made in the higher half of that range. If it's baled much above 60%,

conditions tend to swing in favour of the clostridial bacteria.

Baling grass that is too dry has its problems, too. A drier bale is likely

to undergo too much damaging aerobic activity before anaerobic fermentation

begins. It is also less likely to drop below the desired pH of 5.0, giving

clostridial bacteria yet another opportunity to multiply.

If all goes well, your wrapped bales should dip below pH 5.0 in a few days

and, preferably, under a week. Fermentation will continue slowly for a

few more weeks, but the critical pH has been reached.

There are ways a contractor can help things along. If they use a baler that

chops the grass as it is fed into the baling chamber, this will speed the

process. They can also spray the cut grass with an inoculant, containing

good bacteria and enzymes, or an acid-based preservative. Some would

consider one of these options essential for any cut grass that has been

rained on, or for grass that is drier than desirable.

The risk

The faster the bale reaches a pH of 5.0 or less, the less chance that

clostridial organisms can take hold. Higher pH levels can also provide a

suitable environment for listeria.

Bales made with a moisture content greater than 60 per cent also stand a

greater chance of becoming badly affected by Clostridium botulinum.

Hints for making good balage

These measures will not only improve balage quality, but reduce the risk

of spoilage.

Using quality grass with a high sugar content increases the chances of

making good balage.

Use grass before it's too mature and stalky. Younger grass will make much

better balage. Poor quality grass will always make poor quality balage.

Cut the grass later in the day, when the sugar content will be higher.

Cut only when you're confident you can get it baled and wrapped before it

rains.

If your cut grass does get rained on, tell the contractor to use an

additive which will help the fermentation.

Do what some farmers do: pay extra to have inoculant applied every time

you make balage.

Wrap bales as soon as possible. Asking for extra layers of plastic will

add about $3 a bale. It is good insurance against holes and your bales

are likely to keep longer.

Do not make balage from a paddock contaminated with dung, especially one

fertilised with poultry manure. Move bales as soon as possible after

wrapping to their final resting place, and do not move them again.

Check bales regularly for holes and tape them up.

Get the moisture content right at baling to increase your chances of

good balage. Wetter balage not only runs an increased risk of clostridial

spoilage, it can also be damaged through freezing. If the grass is getting

too dry, make hay.

Never use a tedder unless it allows you to get it baled before rain strikes.

Tedding usually shouldn't be necessary - the "fluffing up" that results will

only serve to put more air into the finished bale, which you don't want.

Ensure the rake doesn't contact the ground, stirring up dust which can put

clostridial bacteria on the grass.

Avoid baling small-animal carcasses with the grass.

Store balage with some shelter from the sun. Fermentation is at its best

in the range of 15 to 25degC. Higher temperatures favour clostridial

bacteria, so avoid storing balage where its temperature is likely to

exceed 30deg.

The more even the temperature during the fermentation and storage,

the better.

Don't stack the bales.

When feeding a bale out over several days, close the plastic back over the

opening to keep air out as much as possible.

Clostridial spoilage arises from the production of butyric acid. The

balage will be sour and foul smelling, often like ammonia. You are likely

to find evidence of slime moulds. Never feed it out. In fact, do not feed

out any mouldy balage, even if it still has that distinctive balage smell.

Dr Simone Hoskin, senior lecturer in ruminant and equine nutrition at

Massey University's Institute of Veterinary, Animal and Biomedical Sciences,

believes pit silage is more risky than balage because of its generally

higher moisture content.

"Wrapped silage (balage) can be a great feed ... and can be very cost

effective," she says, "although once a bale has been opened it should be

used within a few days unless it is very cold or snowy weather, in which

case it can be fine for up to 10 days - otherwise you can get secondary

fermentation."

Dr Hoskin considers the risk of botulism poisoning low, provided the balage

is of good quality.

It is hard to escape the conclusion that New Zealand appears to be a

low-risk area for botulism poisoning in stock. There have been no recorded

cases of it in any species at Massey University in at least 10 years. It

is known in birds, but there do not appear to have been any cases reported

in cattle in this country. Even if cattle cases have come to light here,

they would certainly rate as extremely rare.

Overseas, livestock have not been so lucky. Feed-related outbreaks of

botulism have not only been linked to silage and balage - big-bale lucerne

hay and oaten chaff have also been a source. This shows that any spoiled

feed (not just balage) could potentially carry a risk of botulism and

should never be fed out.

Test for quality

Balage being bought should be tested for quality and the price should

reflect the quality, says Massey University equine nutritionist Dr Simone

Hoskin.

Most major suppliers get their product tested, she says. "If they haven't,

you are quite within your rights to ask for it to be tested, or get it

tested yourself."

A fresh 500g sample (preferably from the centre of a bale) can be sent by

courier in a sealed plastic bag to a variety of labs for analysis, including

the Massey University Nutrition Laboratory.

Keep your friends

If you're feeding balage out by hand, wear your wet weather gear, including

gloves. The smell of balage is quite invasive, and not everyone will enjoy

Eau de Silage. It's one of those smells that keeps on giving!

What can go wrong?

The cut grass can be rained on. This leaches sugar from the grass and can

result in poor balage. Rain can also splash clostridial bacteria from the

soil on to the grass, which can cause bad fermentation.

The bale plastic can be punctured, either while being transported, by

birds, vermin, porina moths emerging from the ground beneath the bales, or

by stalky material poking through the plastic. (see "How to prevent holes").

The wrong kinds of bacteria can take hold, ruining the bale and risking

botulism poisoning in horses and cattle if fed out.

The grass may not have enough sugar to fully ferment, resulting in an

unstable bale and increasing the chances of spoilage.

|

|

Taken from the instruction sheet for Silotite wrapping film,

to show what an exact operation bale wrapping is.

INSTRUCTIONS FOR USE

This blend of Silotite is formulated for use in conditions where UV

radiation levels do not exceed 80 kiloangleys, and at 55%-75%

maximum pre-stretch, (65% on square bales). In extreme temperatures,

it is advisable to reduce pre-stretch to 55%. On some mini-wrappers,

pre-stretch may be less than 55%.

Care of reels

- Store reels on their ends in the dry, and out of direct sun light.

- The ideal storage temperature is 15-20 deg.C. Keep reels in boxes,

and condition at ambient temperatures prior to use.

- Take care not to damage reels during handling, in particular reel

edges should be protected.

- Cover reels left on wrapper to keep out moisture. We reommennd that

reels are used within two years of purchase.

Application

- Ensure that bales are well shaped, dense, and ideally of 40-50% dry

matter (DM). For haylage, up to 60% DM.

- Wrap within 2-3 hours of baling.

- Ideally wrap at stacking point, and in the shade.

- Square bales must be straight sided as any concave surfaces will

produce air pockets when wrapped and possible spoilage.

- Ensure that wrapper is set correctly for film width and bale size in use.

- Ensure that pre-stretch unit (PSU) rolers are thoroughly and regularly

cleaned to remove 'tack' and other contaminants, in accordance with

th wrapper manufacturer's instructions.

- Load bale, and place film reel on PSU so that the outer film surface on

reel will face inwards towards bale when applied (see diagram 1)

- Adjust height of PSU where possible so that centre points of reel and

bale are horizontally aligned.

- Thread and attach film as per wrapper instructions.

- To calibrate wrapper on first bale, count number of turntable or sweep

arm turns required to cover the bale once. Then add one turn, and

repeat the total. (2)2 method).

- When wrapping using a continuous tubeline system, a minimum 6

layers of film must be applied to the joins between the bales.

- Remember that any increase in bale size or irregularity in shape will

mean that more turns will be needed.

- Apply minimum 4 layers of film to all areas of the bale, using the

above 2+2 method, and minimum 50% overlap. Where DM levels

exceed 50%, or square bales are being wrapped, a minimum of 6

layers of film should be applied (2+2+2 method).

- Independent trials have also indicated economic benefits from the

application of 6 layes of film for normal silage.

- We would also recommend the use of a minimum 6 layes of film on

course crops such as kaleage.

- Final width of film as measured on the flat end of a round bale should,

with 500mm film, for example, be 380mm 410mm, and with 750mm

film 580-610mm (see diagram 2). For 250mm or 360mm film

reduction in width should not exceed 20%. Should film width vary

sinificantly outside these limits, stop wrapping and ascertain cause.

Refer to wrapper manufacturer with reference to PSU gearing.

- Ensure that on completion of wrapping, bales are not damaged when

they are off loaded

- Cut end of film should be tucked in securely as possible.

- Ensure that no holes or splits are present in film on bales prior to

stacking. If so, apply extra film. Holes or splits through all film layers

indicate either bird or mechanical damage, or insufficent film applied.

They are not indicative of film faults.

Stacking

- Choose a storage site away from trees and very exposed areas. Do

not stack bales too close to hedges. Store away from any water

courses:specific advice is available from the Water Authority.

- Chose a well drained level site, devoid of sharp objects which could

damage film. A sand or gravel surface is ideal.

- Stack bales immediately after wrapping, and certainly within 12

hours. Use a purpose-built handler, and never a spike.

- Do not stack more than 3 high. Bales of low DM should only be stored

in single layers.

- Repair any damage immediately using a suitable UV-protected tape.

- N.B. Even minor damage to film can result in spoilage to fodder.

- Protect bales from birds by first placing a layer of tyres over the top

of the stack, and then applying a close-woven polypropylene net,

secured at ground level.

- Fence off stack from livestock if necessary.

- Install vermin bait stations around stack perimeter, and replenish as

required.

- Inspect stack regularly, and repair any damage immediately.

- Feed bales within 12 months of wrapping.

Precations

Do not wrap bales tied or netted with products which are chemically

reactive to polythene such as some types of sisal twine.

Do not wrap in the rain, as this may impair seal between layers.

Do not wrap bales which have been treated with a sulphur-based

additive.

Remove any visible spoilage within the bale on opening, before feeding

to livestock. Fodder which contains spoilage must not be fed to

breeding stock or horses.

Keep film and wrapped bales away from fertiliser, herbicides, mineral

oils, etc, which can accelerate film degradation.

High DM Bales

When considering the wrapping of bales of very high DM (60%+), eg

haylage for horses, it should be remembered that the

fermentation/preservation process which normally consumes any

remaining oxygen within a moist silage bale is usually very slow or even

non-existant. This means that irrespective of how many additional film

layers have been applied, the continuing presence of oxygen may well

allow the development of moulds etc. and consequent spoilage. The use

of a suitable additive at baling may help in these circumstances. Forage

containg spoilage must not be fed to livestock, in particular horses and

all breeding stock.

Used Silotite

Do not burn or bury used film on farm, as Silotite may be recycled or

incinerated as an energy source where appropriate facilities exist.

Health & Safety

Health and safety requirements should be observed at all times. High

noise levels can occur during wrapping. We recommend the use of

suitable ear defenders. Do not allow unauthorised persons, especially

children, to have access to the balewrapper or the bales when stacked.

In the event of complaint

If you are dissatisfied with any Silotite rel either before or during

wrapping, do not use. Replace in original carton and contact your

supplier with full details of your complaint within 14 days.

Reels will only be replaced if they are found by Bpi.agri to be faulty.

Because there are many possible causes of poor quality farage, which

are beyond the control of Bpi.agri, the liability of the latter is restricted to

film replacement only and claims cannot be accepted for consequential

loss.

|

|

Compiled, formatted, hyperlinked, encoded,

and copyright © 2007,

All Rights Reserved.

All Rights Reserved.

|